Elevate your lab’s performance with this high-precision automation, engineered to tackle the modern challenges of life science workflows.

Designed and manufactured in the U.S.A., this system offers unparalleled value and customization to suit your specific applications.

• Intelligent Automated Pipetting: Streamline your processes with advanced pipetting technology.

• Simplified Complex Pipetting: Effortlessly handle intricate pipetting tasks.

• High Throughput for Large Volumes: Achieve rapid processing without compromising accuracy.

The Lynx Liquid Handling Robot Series Platform (Workstation) is designed to meet the current application needs of today’s life science companies. Through the implementation of Volume Verified Pipetting (VVP) technology in the 96/24 VVP & f8 VVP pipetting tools, we now directly measure liquid entering and leaving the tip volumetrically, creating a final validation report that methods are accomplished as programmed. These VVP pipetting tools take the guesswork out of pre-validated methods running water, reagents with dye or multiple dispenses over a balance to ‘average out’ how individual liquids may be handled. Now, validated reports are the standard, with actual volumes recorded at each liquid aspirate/dispense activity. Reports are stored in the same folder as all the other standard sample tracking information, such as sample bar codes, tip and plate bar codes, reagent lot number, and more. Combine VVP technology with your choice of multiple deck sizes, Standard Volume (SV) syringe-based 96 & 384 pipetting tools, microplate gripper tools and vision scanning tools to configure just about any combination for a liquid handling robotic system equipped to accomplish your application.

Aspiration and dispense of the liquid sample is driven by the precise control of vacuum and positive pressure. A volumetric liquid transfer is accomplished in each channel by the coupling of a solenoid valve to a silicon chip based MEMS flow sensor in a closed loop real time environment, where the actual flow rate of a liquid is monitored. This allows liquids with different physical properties to flow into/exit the tip while automatically accommodating for temperature and viscosity differences.

VVP technology also provides Liquid Level Detection (LLD) for each channel utilizing clear tips in both the 96 & 8 channel pipetting tools. The system creates an outward flow of air and monitors this airflow until a solid meniscus is detected. The Residual Volume within the well is then calculated based on the vertical height of the tip at the contact point with the solid meniscus and the well volume parameters.

Short sample or Air-In-Sample diagnostics is established by the monitoring of all channels with millisecond sampling analyzing the flow rate of the liquid into each tip. Any disruption of the samples flow rate by air entering a channel traps Short Sample Error. The end user may predetermine how to handle this Short Sample Error, including an on-the-fly retry of the aspiration, dispense all samples

back to the source well, or transfer the volume and report the actual ‘short’ volume transferred.

The Short Sample diagnostics technology is employed to verify that no air is aspirated as the Tip Tracking function is utilized. If the sample is aspirated faster than the tip tracks down, the Tracking Error is trapped for the individual channel(s).

Volume Verified Pipetting technology from Dynamic Devices validates liquid transfers, with full liquid handling diagnostics and volumetric sample tracking. Combinations with our standard spreadable 8 tip and 96 / 384 channel syringe based pipetting tools ,linear motion technology, microplate gripper tools, machine vision error handling and bar code scanning, the most powerful liquid handling robot can be configured to fit just about any laboratory automation application.

Why Choose the Lynx LM Series Liquid Handling Robotic Platform? Absolute Positioning with Linear Magnetic Motors & Encoders Linear motors and encoders provide superior positional accuracy, precision and repeatability to the mechanical rotation-to-translation mechanisms such as racks & pinions or belts & pulleys commonly found in laboratory liquid handling instruments. In addition, linear motors and encoders provide increased speeds reduced maintenance and on the pipetting tool positional encoding.

Supreme Flexibility with an Unrestricted Worktable

Each Lynx worktable position includes an SBS compliant microplate footprint that provides organizational flexibility with any combination of plates, tips or disposables. The superior strength in the instrument chassis and vertical drive allows the Lynx to load 96 or 384 tips from any of the possible 66 worktable locations. This flexibility, combined with a complete disposable tip line each available in an SBS free standing tip box, provides a flexible yet highly functional worktable.

Advanced Motion Controls

The Lynx offers the latest linear drives and advanced motion controls commanding highly precise positioning and repeatability with virtually no maintenance. The per motion axis modular architecture includes a solo high flex cable with a single connector containing both the power and communications, providing simplicity and reliability.

Open Design For Flexible Integration

Microplate gripper options give the Lynx flexible integration capabilities from simple pipette head grippers to 6 axis SCARA robots that can reach off deck to incorporate other peripherals. The open chassis design allows integration from all 4 sides, as well as horizontal conveyor options and vertical incorporation through the worktable.

Low Maintenance Solid Mandrel Tip Loading

The Solid Mandrel (SM) tip adapters for the loading of disposable pipette tips has abolished the need for maintaining high maintenance components like rubber O-rings and tip seals. The SM tip loading eliminates the need for a 3 or 6-month preventive maintenance service by excluding the highest maintenance component on the robot.

Simplified Programming with Method Manager 4.0

Method Manager 4.0 provides an intuitive and simplified way to program your methods, import files, export your pipetting data, and manage pipetting diagnostics and error handling routines.

Award-winning Volume Verified Pipetting (VVP) technology represents the very latest in air-based 8, 24 & 96 multi-channel pipetting.

Highly sensitive in-line flow sensors integrated into each and every channel translates to unique pipetting competencies

Liquid Level Detection (LLD) with VVP

Independent-channel LLD on all liquid types is performed via controlled micro-releases of air from the distal end of the tip and subsequent monitoring of pressure changes associated with meniscus (or bubble/foam) interference. A residual volume based on the confirmed meniscus height and labware definition is calculated. Any pipetting discrepancies experienced are addressed via several user-defined error recovery options.

Air-based VVP technology accomplishes robust LLD without the need for more expensive carbon-impregnated (capacitance-based LLD) disposable tips. For the best pipetting results, be sure to use D2-brand ‘performance-certified’ clear disposable tips.

Pipetting Diagnostics with VVP

VVP performs continuous millisecond analysis of flow rates for each liquid channel. A disruption in the expected average flow rate, produced either by air entering the channel (i.e. ‘short or no sample’) or a blockage (i.e. clot/clog) triggers an alert.

Diagnosed pipetting errors are addressed automatically ‘on-the-fly’ via user-defined error recovery options.

Independent control of each channel affords the freedom to isolate and disable only the offending channel(s), allowing the method to continue without interruption.

Upon method completion, a final Error Report file is generated.

Featuring next-gen integrated flow sensor technology. Fast and flexible, perfectly suited for liquid handling in single microliter to milliliter volumes.

Traditional syringe-drive air-based pipetting; uniform volume across all channels. An economical solution for many liquid-handling applications such as plate stamping. Single, row and column tip pick up. For 24, 96, 384 & 1536-well plate-based liquid handling routines.

| Pipetting Tool | DDX96 60 μL

non-filtered |

DDX96 340 μL

non-filtered |

DDX96 1250 μL

non-filtered |

LXB96 200 μL

non-filtered |

LXB96 300 μL

non-filter |

LXB96 1250 μL

non-filtered |

| High Volume

96ST Head |

1.0 μL – 60 μL

(35 μL filtered) |

1.0 μL – 340 μL

(230 μL filtered) |

1.0 μL – 1000 μL

(1000ul filtered) |

1.0 μL – 200 μL

(150 μL filtered) |

1.0 μL – 300 μL

(250 μL filtered) |

1.0 μL – 1000 μL

(950 μL filtered) |

*lower volumes may be achieved under optimal conditions

| Pipetting Tool | DDX384 30 μL

non-filtered |

DDX384 70 μL

non-filter |

DDX384 (96 format) 70 μL

non-filtered |

LXB384 30 μL

non-filtered |

LXB384 70 μL

non-filtered |

| Low Volume

(384) 96ST Head |

X | X | 1.0 μL – 70 μL | X | X |

| 384ST Head | 1.0 μL – 30 μL

(15 μL filtered) |

1.0 μL – 70 μL

(50 μL filtered) |

X | 1.0 μL – 30 μL

(15 μL filtered) |

1.0 μL – 70 μL

(50 μL filtered) |

*lower volumes may be achieved under optimal conditions

Positional Accuracy and Reproducibility

Linear drive motors coupled with x/y axes positional encoders provides unparalleled accuracy and zero drift over time. < 0.1 mm positional resolution allows robust pipetting to high-density 1536-well plates.

Lynx incorporates a series of enabling technologies for robust performance and reduced maintenance.

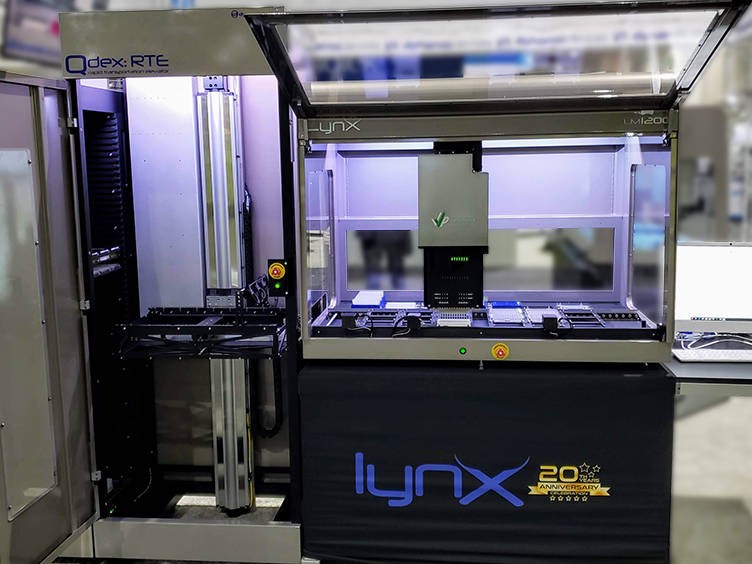

Dynamic Loading & Storage Integration

We’re excited to introduce to you the NEWEST member of the Dynamic Devices product line Qdex! With the need for speed and ultimate flexibility, the NEW Qdex will solve your workflow bottlenecks holding up to 60 trays at a time. As displayed at SLAS 2020, Qdex is available for continuous operation with dynamic loading giving you uncompromising performance.

Virtual Deck | Faster Access | Random Access | Batch Processing | Continuous Loading | Multi-User Availability | SBS & Custom Labware | 4x the capacity

No more waiting to load or unload plates or trays

Normalize 270 plates in less than 4 hours

Exchange a tray of 9 plates in 30 seconds

18 virtual deck positions available

|

|

|

| Seamless Integration with Lynx Workstation | Dynamic Loading/Unloading of Trays | Holds up to 60 Trays at a Time |

• Genomics

• Proteomics

• CellOmics

• Drug Discovery

• Applied Science

• Microarray

Lynx Platform Decks Sizes

Sizes & Capacities

Flexible, space-efficient decks to fit your ideal throughput and walk-away time; 5 models to choose from:

| Platform Deck | Length | Width | Height | Deck Positions (#’s) |

| LM1800 | 75“ | 36“ | 40“ | 60-66 |

| LM1200 | 52“ | 36“ | 40“ | 42 |

| LM900 | 40“ | 36“ | 40“ | 30 |

| LM700 | 28“ | 26“ | 26“ | 12 |

| LM730i | 24“ | 24“ | 30“ | 18 |

Please fill out the following form about your inquiry.