Company A is a plant breeding company specialized in developing new vegetable species to actively contribute to food supply and vegetable consumption all over the world. Developing these new varieties takes a lot of time, effort and biochemical applications as DNA/RNA extraction, DNA/RNA purification and other nucleic acid related applications. In order to keep moving forward as a company, company A is constantly looking for solutions to improve their way of working which will affect their overall goal as a company.

A part company A’s activities is done by performing plate transfers from 96 to 384 formats, and plate transfers from 384 to 96 formats on a high throughput and magnetic bead based DNA purification. In the last years, Company A has experienced a growing demand in these tests. This project is designed to design a liquid handler that will perform below named applications in a higher throughput.

The main goal of the project is to have an automated solution, able to process flexible numbers of source and destination plates for plate transferring as well as cherry picking. Besides this, a magnetic bead based DNA purification for up to 96 samples in a very quick and successful way was one of the goals.

The demands on the automated solution are:

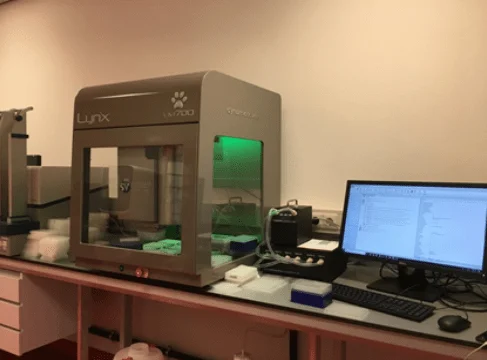

After off- and on-site validation of all described assays the outcome showed the Dynamic Devices LM700 being sufficient for Company A’s needs, giving them more hands-off time, more flexibility and a higher throughput.